Global Infrastructure Demands Drive Innovation: How Specialized Chinese Geotextile Manufacturers Like G-Tex® GE are Meeting Complex Project Needs with Advanced Functional Fabrics

Dalian, China – The global geosynthetics market is witnessing a paradigm shift, moving beyond basic separation and filtration functions towards highly engineered, application-specific solutions. This evolution is driven by increasingly complex infrastructure projects, stringent environmental regulations, and the need for long-term asset durability. At the vanguard of this shift are specialized Chinese geotextile manufacturers who have invested heavily in R&D and advanced manufacturing to produce next-generation materials. Among them, Dalian GeoMax Synthetics Co., Ltd., with its flagship brand G-Tex® GE, exemplifies this trend, offering a comprehensive portfolio of functional geotextiles that cater to niche but critical engineering challenges worldwide.

The Engine of Growth: Data and Drivers

The global demand for high-performance geosynthetics continues to surge, fueled by mega-trends in urbanization, climate resilience, and sustainable construction. While specific market reports vary, the consensus points to sustained growth in the geotextile segment, particularly for nonwoven fabrics used in environmental protection and transportation. Key drivers include:

- Environmental Protection Mandates: Strict regulations for landfill construction, mining rehabilitation, and water containment are mandating the use of certified, high-barrier geotextile fabrics.

- Infrastructure Renewal: Aging roads, railways, and waterways require advanced reinforcement and drainage solutions where functional geotextiles play a pivotal role.

- Smart Construction: The integration of monitoring and identification features, such as those found in Logo Inkjet coding geotextile and conductive geotextile, is becoming a value-added standard for large-scale projects.

Beyond Standard Fabrics: The Rise of Engineered Geotextile Solutions

Modern engineering projects often face unique site conditions—corrosive leachate, prolonged UV exposure, need for subsurface moisture management, or requirements for electrical leak detection. Standard geotextiles are insufficient for these scenarios. This is where the technical prowess of a specialized Chinese geotextile supplier like Dalian GeoMax Synthetics becomes crucial. The company’s China geotextile plant is engineered not for mass production of generic goods, but for the flexible manufacture of tailored solutions.

A Portfolio of Functional Innovation

G-Tex® GE has developed a range of specialized products that address specific functional needs:

- Wicking Geotextile: Engineered with capillary action to actively draw moisture laterally, preventing water accumulation and frost heave in subgrades, a critical solution for cold-region infrastructure.

- Anti-UV Geotextile: Formulated with enhanced UV stabilizers to resist degradation when exposed for extended periods during construction or in permanent exposed applications, significantly extending service life.

- Conductive Geotextile: Integrates conductive elements for use in landfill liner leak detection systems (LLD), allowing for precise monitoring of geomembrane integrity—a vital tool for environmental compliance.

- Orange Geotextile & Colored Variants: High-visibility Orange geotextile improves safety and installation accuracy. A spectrum of colors is available for project coding, aesthetic blending, or brand identification.

- PP Nonwoven Geotextile with Custom Properties: Beyond standard PP nonwoven geotextile, the company modifies polypropylene formulations for chemical resistance or enhanced durability in harsh environments.

G-Tex® GE offers geotextiles in various colors, including high-visibility orange, for project coding and safety.

The Manufacturing and Quality Backbone: Why G-Tex® GE Stands Out

The ability to reliably produce these advanced materials stems from a deep-rooted commitment to quality and continuous improvement. Dalian GeoMax Synthetics Co., Ltd. operates a vertically integrated system that controls the process from raw material to certified finished product.

1. Certified Production Excellence

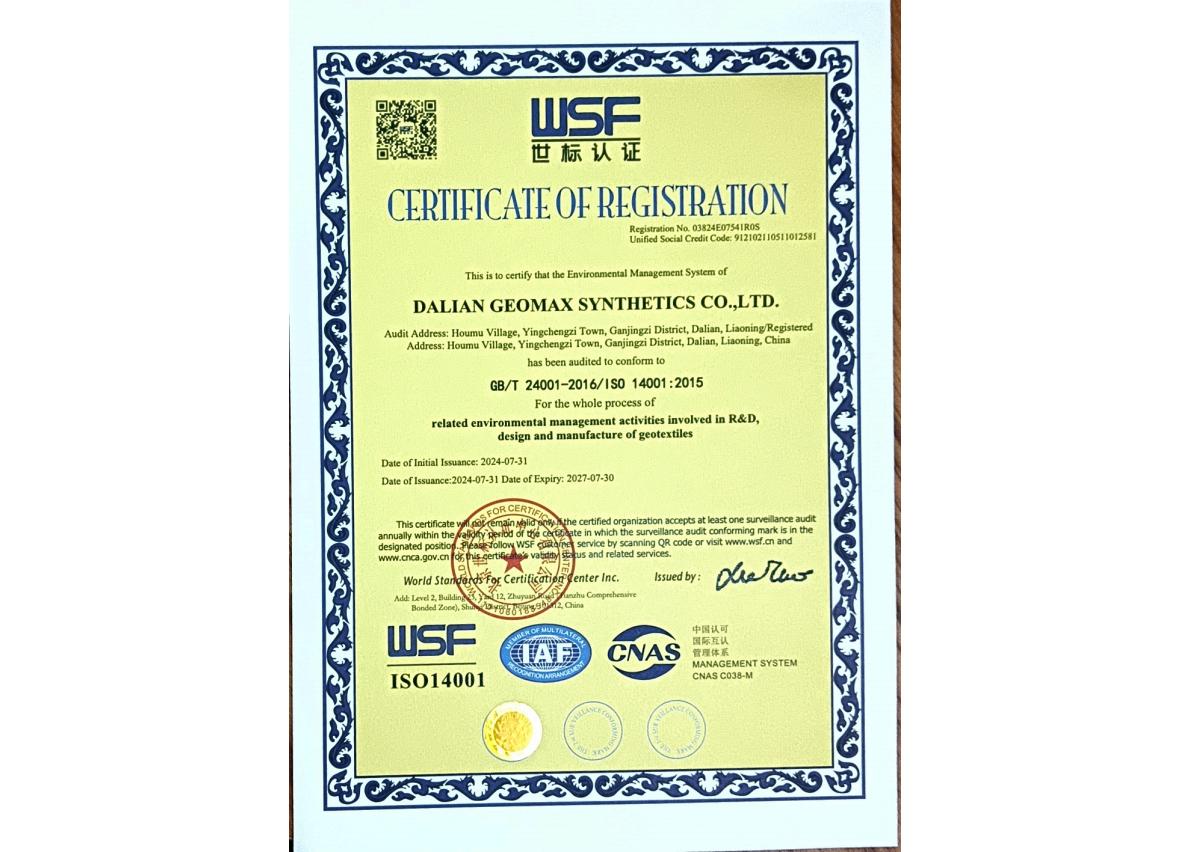

The company’s manufacturing philosophy is built on international standards. It is certified to ISO9001 (Quality Management), ISO14001 (Environmental Management), and ISO45001 (Occupational Health & Safety). Its products consistently meet or exceed ASTM, AS, ISO, DIN, and GB/T standards, a testament to its capability as a world-class Chinese geotextile manufacture.

International certifications underpinning G-Tex® GE's quality and environmental management systems.

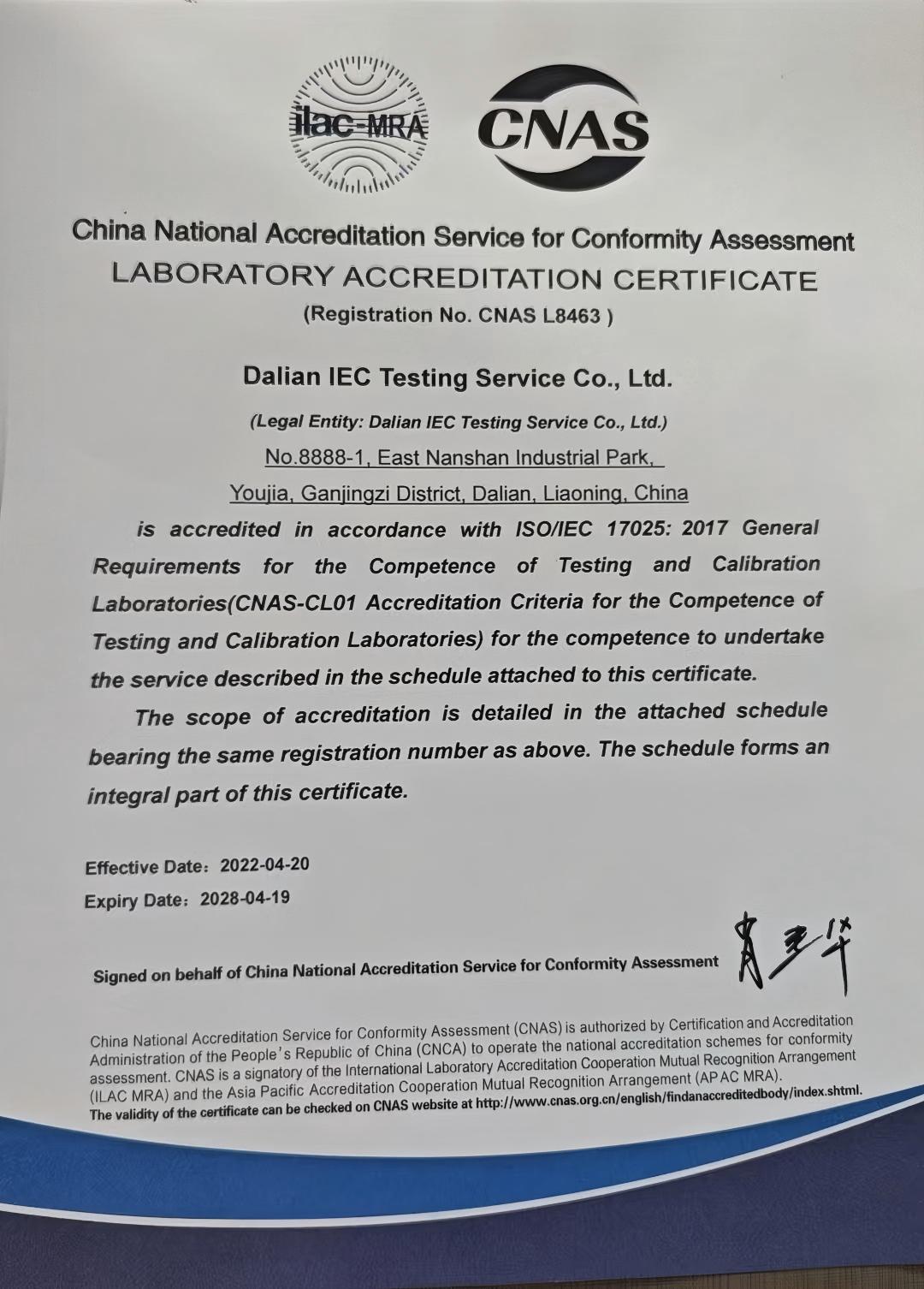

2. Independent, Internationally Recognized Testing

A unique differentiator is the company’s subsidiary, Dalian IEC Testing Service Co., Ltd., which holds CNAS (China National Accreditation Service) laboratory accreditation. This accreditation is mutually recognized by over 70 countries through ILAC and APLAC agreements. For global clients, this means product test reports from Dalian GeoMax carry international credibility, removing a significant barrier in the procurement process for Chinese geotextile products.

CNAS accreditation ensures internationally recognized testing for all G-Tex® GE products.

3. Proven Global Project Legacy

The true test of any geosynthetic product is its performance in the field. G-Tex® GE products have been deployed in over 30 countries across six continents. Their materials have been critical components in major landfill projects like Shoal Bay Landfill (Darwin), Thilawa Landfill (Myanmar), and the Great Southern Landfill, supplying hundreds of thousands of square meters of heavy-duty cushion and separation geotextiles. This extensive portfolio provides engineers with proven, case-study-backed confidence.

G-Tex® GE geotextiles in application for erosion control and riverbank protection projects.

Conclusion: Partnering for Future-Proof Infrastructure

The future of civil and environmental engineering lies in materials that are not only strong and durable but also intelligent and multifunctional. The trend towards Logo Inkjet coding geotextile for traceability, as highlighted in related industry analyses, is just one facet of this broader movement. The ability to specify wicking, anti-UV, conductive, or custom-colored geotextiles allows engineers to design more resilient, efficient, and compliant structures.

For project owners, consultants, and contractors worldwide, partnering with an innovative and certified Chinese geotextile manufacturer like Dalian GeoMax Synthetics (G-Tex® GE) offers a strategic advantage. It provides access to a blend of scalable production, rigorous quality control, independent certification, and—most importantly—the engineering support to develop material solutions for the world's most challenging infrastructure problems.

Contact Dalian GeoMax Synthetics Co., Ltd. – G-Tex® GE

Discover how advanced functional geotextiles can benefit your next project. Contact the specialists today for technical data sheets, project references, and custom solution consultations.

Website: https://www.geotranstechnology.com

Email: enquiry@geo-textile.com

Phone/WhatsApp: +86 18698655505

Address: NO.8888-1 Southeastern Industrial Zone, Youjia, Ganjingzi District, Dalian, China.