The Ultimate Buyer's Guide to Innovative & Customized Geotextiles

Selecting the right geotextile is no longer just about separation or filtration. In today's complex infrastructure landscape, success hinges on innovation and customization. This guide delves into the advanced world of functional geotextiles, helping you make informed decisions that align with precise project demands and future-proof your investments.

Why Innovation in Geotextiles Matters Now

The global push for resilient, sustainable, and smart infrastructure is reshaping material specifications. Standard PP nonwoven geotextile or basic fabrics often fall short for specialized applications like landfill capping with stringent environmental controls, projects requiring long-term UV resistance, or sites needing moisture management. This is where partnering with a forward-thinking Chinese geotextile manufacturer like Dalian GeoMax Synthetics Co., Ltd. becomes a strategic advantage. Their G-Tex® GE brand exemplifies how Chinese geotextile production has evolved from commodity supply to a hub of technical excellence and bespoke engineering.

Part 1: Understanding Core Functional Innovations

Beyond basic weight and strength, modern geotextiles offer engineered properties. Here’s a breakdown of key innovative types and their applications.

1. Wicking Geotextile

Function: Actively transports moisture laterally away from critical zones (e.g., road subgrades, behind retaining walls) to prevent saturation and instability.

Buyer's Tip: Specify required transmissivity rates and confirm testing standards (e.g., ASTM D4716). Ideal for drainage applications in fine-grained soils.

2. Anti-UV Geotextile

Function: Incorporates stabilizers to resist degradation from prolonged sunlight exposure, crucial for exposed applications like erosion control or temporary covers.

Buyer's Tip: Request UV resistance data per ASTM D4355 or ISO 4892. For a Chinese geotextile plant, verify they use premium-grade polymers with integrated, not just surface-coated, UV protection.

3. Conductive Geotextile

Function: Contains conductive elements (e.g., carbon fibers) for applications in leak detection, grounding, or even smart sensing in landfills or containment facilities.

Buyer's Tip: Clearly define the required surface resistivity (ohms/sq). Ensure the manufacturer can guarantee consistent conductivity throughout the roll.

Part 2: The Customization Spectrum – From Color to Coding

True partnership with a supplier means getting a product tailored to your project's logistical, aesthetic, and performance needs.

- Colored Geotextiles (e.g., Orange Geotextile): Beyond aesthetics, colors like safety orange are used for high-visibility demarcation in construction zones or to differentiate layers in complex geosynthetic systems. A reliable Chinese geotextile supplier should offer a palette beyond standard black or white.

- Logo Inkjet Coding Geotextile: This is a game-changer for QA/QC and branding. Your company logo, product name, batch number, or installation instructions can be directly printed onto the fabric. This reduces misidentification on-site and enhances professional presentation. When evaluating suppliers, ask for samples of their coding quality and durability.

- Reprocessing & Special Forms: Does your project need geotextile fabrics pre-cut into sheets, sewn into geobags, or made into mini rolls for manual handling? This value-added service saves time and labor on-site.

Custom-colored geotextiles, like these from Dalian GeoMax, serve functional and safety purposes beyond standard options.

Part 3: The Dalian GeoMax Synthetics (G-Tex® GE) Advantage: A Case Study in Excellence

When sourcing advanced geotextile solutions, the manufacturer's capability is paramount. Dalian GeoMax Synthetics Co., Ltd. stands out as a benchmark. Here’s why they are a preferred partner for complex projects worldwide:

Integrated "Production, Sales, and Research" Model

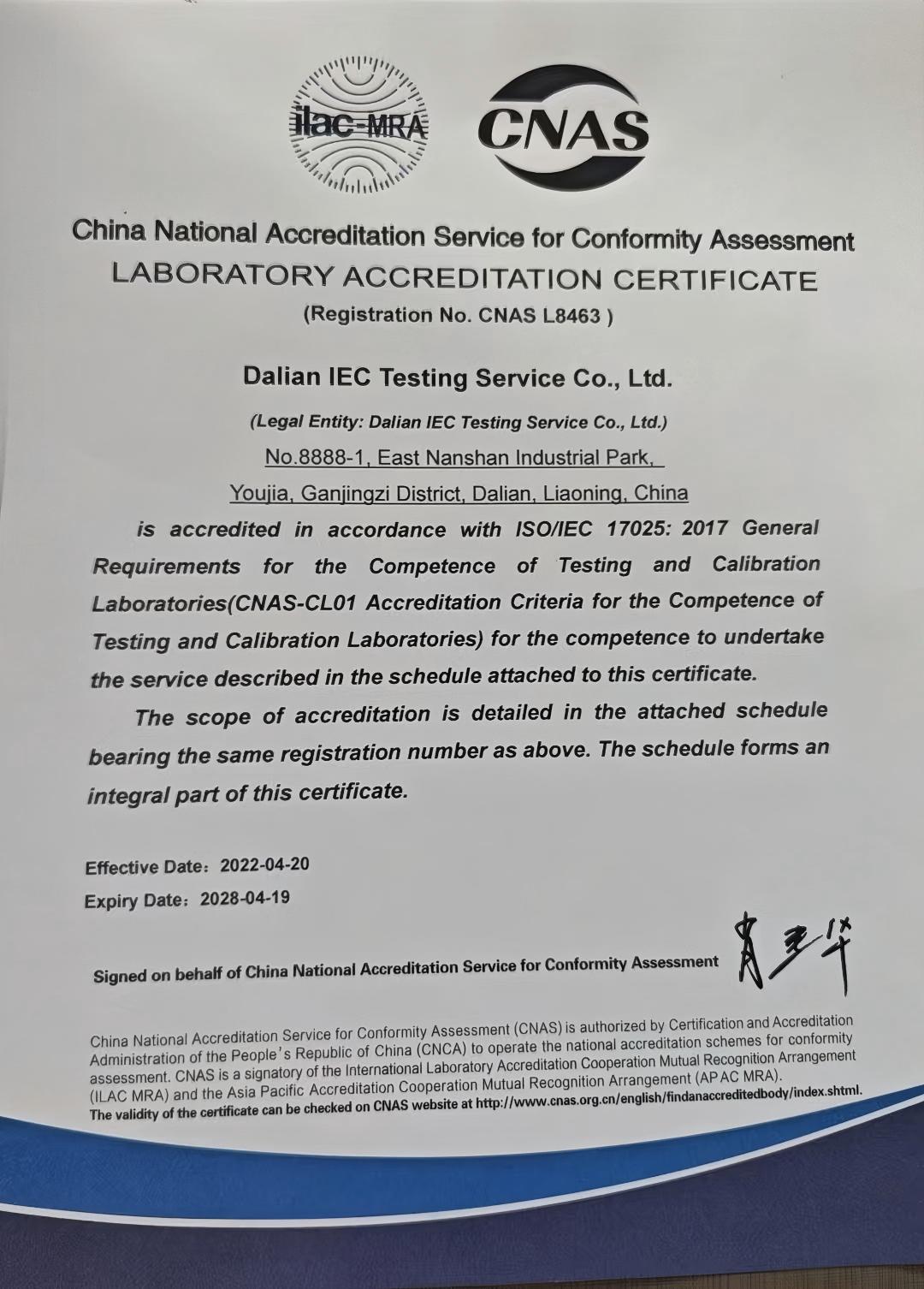

Unlike traders, Dalian GeoMax controls the entire process. Their in-house Dalian IEC Testing Service Co., Ltd., with CNAS laboratory certification (mutually recognized by over 70 countries), is a critical differentiator. This means every batch of wicking geotextile or conductive geotextile can be rigorously tested to ASTM, AS, or ISO standards before shipment, ensuring performance claims are valid.

Proven Project Portfolio: Their products are not just theoretical. They have been deployed in demanding environmental projects like the Shoal Bay Landfill in Darwin (using 38,000m² of heavy-duty cushion geotextile) and the Thilawa landfill project in Myanmar. This track record across diverse geographies proves their ability to meet localized standards and harsh conditions.

Certifications as Trust Signals: Their ISO9001, ISO14001, and ISO45001 certifications, along with status as a national high-tech enterprise, provide a framework for consistent quality and responsible manufacturing—a must for global tenders.

Part 4: Your Step-by-Step Procurement Checklist

- Define the Primary Function: Is it separation, filtration, drainage, protection, or reinforcement? This dictates the base fabric type (e.g., PP nonwoven geotextile for separation).

- Identify Specialized Needs: Will it be exposed to sun (anti-UV geotextile)? Is subsurface moisture management critical (wicking geotextile)? Does the spec require color coding (Orange geotextile)?

- Specify Performance Metrics: Go beyond weight. Define:

- Tensile Strength (ASTM D4632/D4595)

- Puncture Resistance (ASTM D4833)

- Permittivity/Transmissivity (ASTM D4491/D4716)

- UV Resistance (ASTM D4355)

- Evaluate Manufacturer Credentials:

- Do they have in-house R&D and testing (like Dalian GeoMax's IEC lab)?

- Can they supply test reports from an accredited lab?

- Do their customized geotextile options (coding, colors, forms) match your project's logistical needs?

- What is their export experience and project history?

- Request and Evaluate Samples: Get physical samples of the exact Logo Inkjet coding geotextile or geotextile fabrics you intend to order. Check for uniformity, edge integrity, and print quality.

- Clarify Logistics and Support: Understand lead times, packaging (standard rolls vs. mini rolls), and the availability of technical support for installation queries.

Ready to Source Innovative Geotextiles?

For projects demanding more than a standard fabric, partnering with a technologically adept Chinese geotextile manufacture is key. Dalian GeoMax Synthetics Co., Ltd., with its G-Tex® GE products, combines scale, certification, and cutting-edge customization to deliver solutions that perform.

Contact their expert team today for a consultation:

Phone/WhatsApp: +86 18698655505

Email: enquiry@geo-textile.com

Website: https://www.geotranstechnology.com

Disclaimer: This guide is for informational purposes. Always consult with a qualified geotechnical engineer for project-specific material specifications and design.