A Practical Guide to Choosing the Right Geotextile for Your Project

The global push for resilient and sustainable infrastructure has placed geotextile fabrics at the forefront of modern civil engineering. From landfills in Australia to highway projects in Southeast Asia, the correct specification of these synthetic materials is critical for project longevity, cost-effectiveness, and environmental compliance. This guide, drawing on the expertise of leading Chinese geotextile manufacturer Dalian GeoMax Synthetics Co., Ltd. (brand: G-Tex® GE), provides a step-by-step framework for engineers, procurement managers, and project owners to navigate the complex selection process.

Why Specification Matters More Than Ever

Recent industry trends highlight a shift towards performance-based specifications and lifecycle cost analysis. Simply choosing a generic PP nonwoven geotextile is no longer sufficient. Projects now demand materials with verified properties—such as tensile strength, permeability, and durability—tailored to specific site conditions and long-term performance goals.

Step 1: Define the Primary Function

The first and most crucial step is identifying the geotextile's primary role in your project. This dictates the core material properties required.

- Separation: Preventing the intermixing of two dissimilar soil layers (e.g., subsoil and aggregate base). A robust Chinese geotextile with good puncture resistance is key.

- Filtration: Allowing water flow while preventing soil particle migration. This requires careful analysis of the geotextile's apparent opening size (AOS) and permeability.

- Reinforcement: Adding tensile strength to soil structures like steep slopes or retaining walls. High-strength geotxtile fabrics are essential.

- Protection: Shielding delicate geomembranes from puncture. A thick, cushioning geotextile is used, similar to those supplied by Dalian GeoMax for major landfill projects like Shoal Bay and Great Southern Landfill.

- Drainage (Wicking): For applications requiring lateral water transmission within the plane of the fabric. A specialized wicking geotextile is the solution.

Many projects require a geotextile to perform multiple functions simultaneously. Reputable suppliers like Dalian GeoMax Synthetics offer technical consultation to help define these combined requirements.

Step 2: Analyze the Site-Specific Conditions & Environmental Factors

Your project's location and environment are not just details—they are design parameters.

| Condition | Geotextile Consideration | G-Tex® GE Solution Example |

|---|---|---|

| High UV Exposure (Arid regions, uncovered applications) | Degradation of polymer strength over time. | Specify anti-UV geotextile with carbon black or other stabilizers. Dalian GeoMax produces geotextiles with enhanced UV resistance for long-term exposed performance. |

| Aggressive Chemical Environment (Landfills, industrial sites) | Chemical resistance of the polymer (PET vs. PP). | Select polyester (PET) based geotextiles for superior chemical resistance. The company's China geotextile plant produces both PET and PP variants to suit different leachate conditions. |

| High-Visibility or Safety-Critical Areas | Ease of identification and inspection during/after installation. | Utilize Orange geotextile or other high-visibility colors. Custom Logo Inkjet coding geotextile can also be supplied for brand and specification tracking directly on the fabric surface. |

| Need for Monitoring or Electrical Functionality | Integrating sensing capabilities. | Inquire about advanced conductive geotextile options for leak detection or monitoring systems, a specialty area for innovative Chinese geotextile suppliers. |

Step 3: Match Material Properties to Standards and Certifications

Never base your selection on weight (gsm) alone. Key mechanical and hydraulic properties must be verified against recognized international standards.

Critical Properties to Specify:

- Tensile Strength & Elongation: (ASTM D4595, ISO 10319)

- Puncture Resistance (CBR): (ASTM D6241)

- Trapezoidal Tear Strength: (ASTM D4533)

- Apparent Opening Size (AOS): (ASTM D4751)

- Permittivity/Permeability: (ASTM D4491)

- UV Resistance: (ASTM D4355)

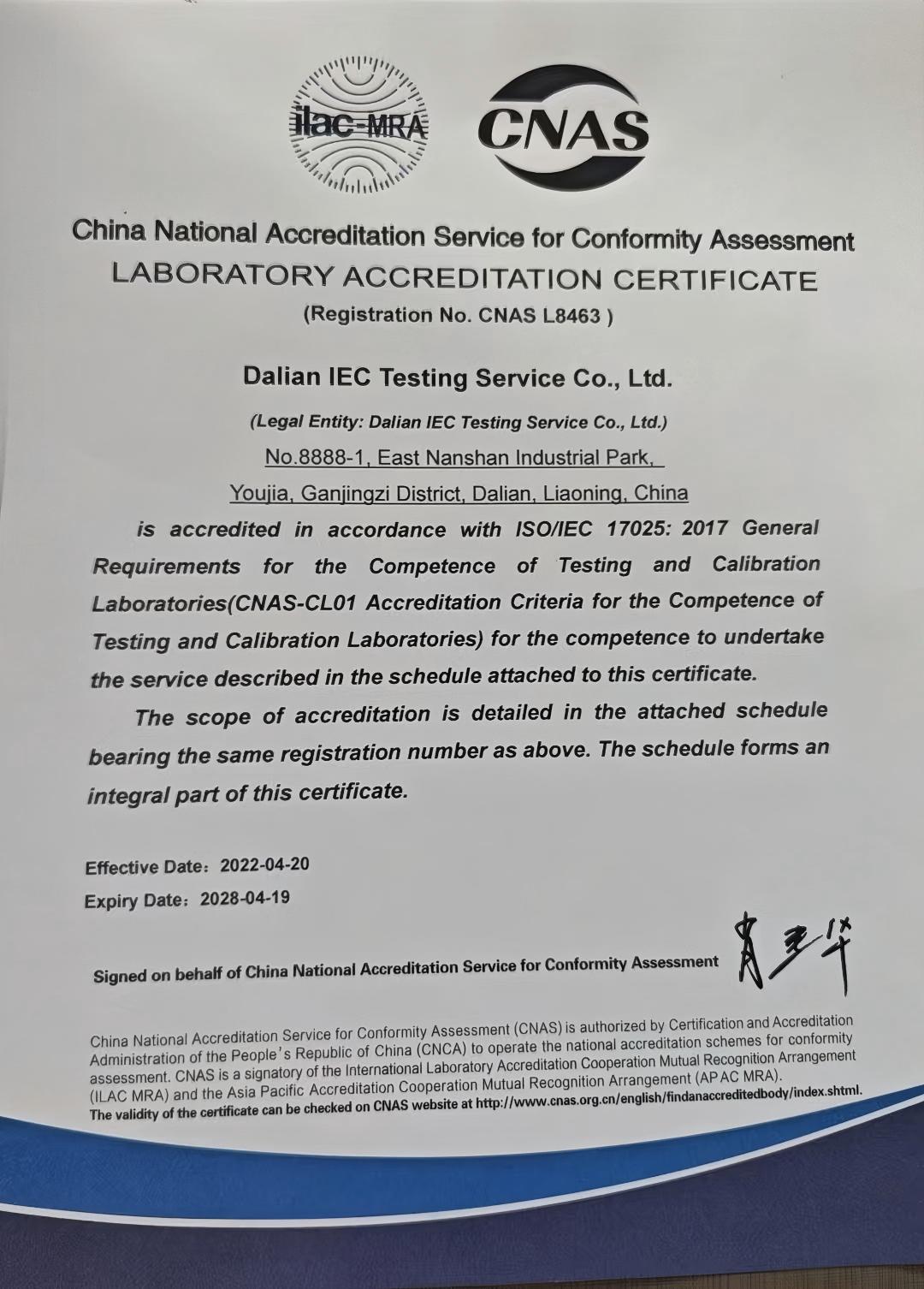

This is where a supplier's credentials become paramount. Dalian GeoMax Synthetics Co., Ltd. stands out as a Chinese geotextile manufacture leader because its products are engineered to meet and exceed a multitude of global standards: German DIN, International ISO, American ASTM, Australian AS, and Chinese GB/T. Furthermore, their in-house laboratory, Dalian IEC Testing Service Co., Ltd., holds prestigious CNAS accreditation (ISO/IEC 17025). This means the test reports they provide for their G-Tex® GE products are recognized and accepted by over 70 countries, providing unparalleled assurance of quality and performance data integrity.

The CNAS accreditation held by Dalian IEC Testing Service is a cornerstone of trust, ensuring international recognition of test data for their geotextiles.

Always request certified test reports for the specific product lot you are purchasing. Reputable Chinese geotextile suppliers like Dalian GeoMax will provide these documents transparently.

Step 4: Consider Logistics, Customization, and Value-Added Services

The best technical product must also be practical to use on site.

- Roll Dimensions & Mini Rolls: For small repair jobs or hard-to-access areas, mini roll geotextiles are invaluable. Dalian GeoMax offers extensive reprocessing capabilities to provide geotextiles in bespoke sizes and formats, including bags and sheets.

- Customization: Does your project require a specific color for zoning or safety? Need your company logo printed on the fabric for quality control and branding? The ability to order Logo Inkjet coding geotextile or Orange geotextile is a significant advantage offered by forward-thinking manufacturers.

- Technical Support: A true partner provides more than just material. From project-specific consultation to guidance on installation techniques for their geotxtile fabrics, this support can prevent costly errors.

Custom-printed geotextile for clear identification.

Mini rolls offer flexibility for small-scale projects.

Step 5: Implement a Quality Assurance Protocol

Your responsibility doesn't end at purchase. Implement a simple QA checklist:

- Pre-Shipment Inspection: Request and review mill test certificates (MTCs) from the China geotextile plant.

- Upon Delivery: Check roll labels for product type, weight, and batch number. Inspect for any visible damage during shipping.

- Independent Testing (For Critical Projects): Consider sending samples from the delivered rolls to a third-party lab for verification against the specified ASTM, AS, or ISO standards. The fact that Dalian GeoMax's sister company is a CNAS-accredited lab speaks volumes about their confidence in product consistency.

Conclusion: Partnering for Performance

Selecting the right geotextile is a systematic process that balances function, environment, standards, and practicality. In today's market, partnering with a certified and innovative Chinese geotextile manufacturer like Dalian GeoMax Synthetics Co., Ltd. (G-Tex® GE) provides a significant edge. Their combination of a full ISO 9001, 14001, 45001 certified management system, in-house CNAS-accredited testing, deep experience in major international projects (from the Thilawa landfill in Myanmar to Australian landfill caps), and a flexible approach to producing wicking geotextile, anti-UV geotextile, conductive geotextile, and custom solutions, makes them a reliable source for engineers worldwide.

By following this guide and engaging with technically proficient suppliers, you can ensure your infrastructure project is built on a foundation of quality, innovation, and long-term reliability.

Ready to specify with confidence? Contact the experts at Dalian GeoMax Synthetics to discuss your project's specific geotextile needs.

Dalian GeoMax Synthetics Co., Ltd. (G-Tex® GE)

Website: https://www.geotranstechnology.com

Email: enquiry@geo-textile.com

Phone/WhatsApp: +86 18698655505

Address: NO.8888-1 Southeastern Industrial Zone, Youjia, Ganjingzi District, Dalian, China.